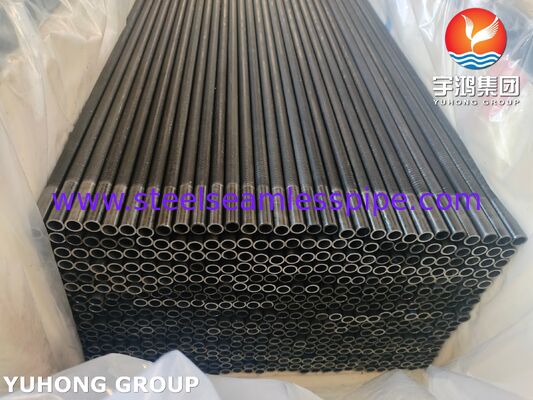

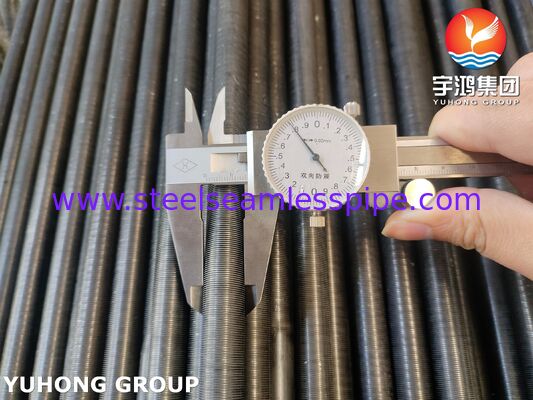

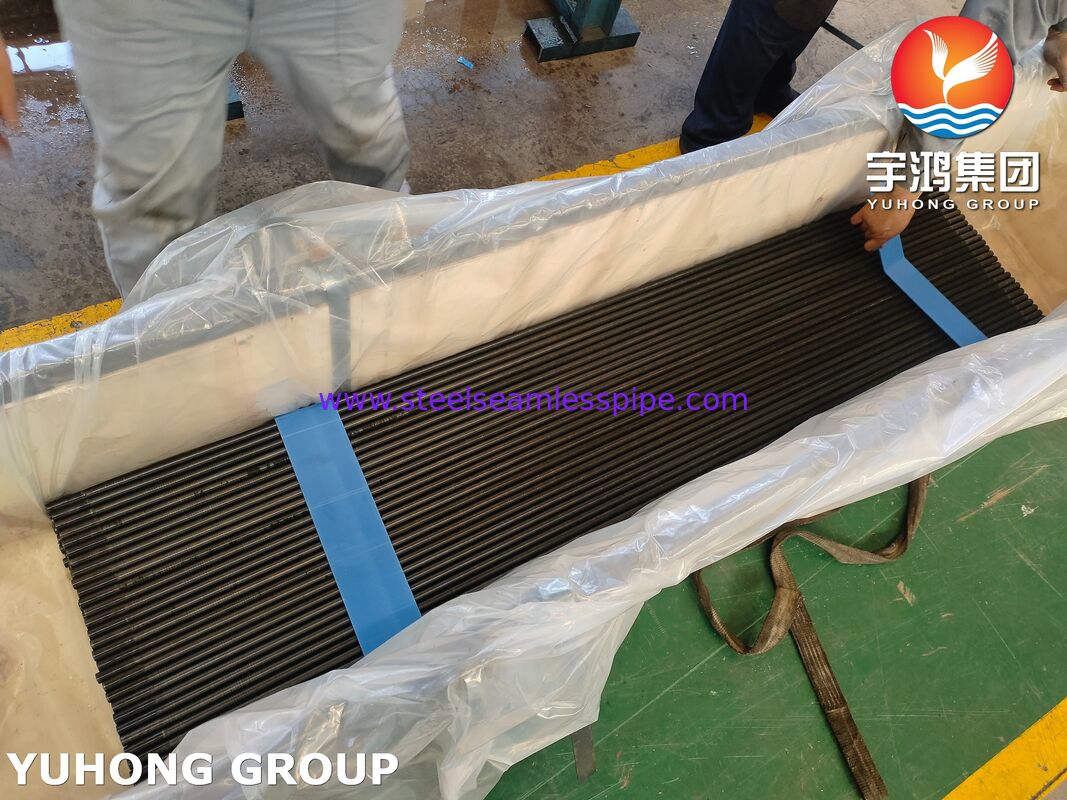

Low Fin Tube is a high-efficiency heat exchanger tube where the outside surface area is significantly increased through the formation of a spiral pattern of low, integral fins. The "A179" designation refers to the base material specification (ASTM A179 for seamless cold-drawn carbon steel tubes), while "Low Fin" describes the fin geometry.

1. Key Manufacturing & Design Features

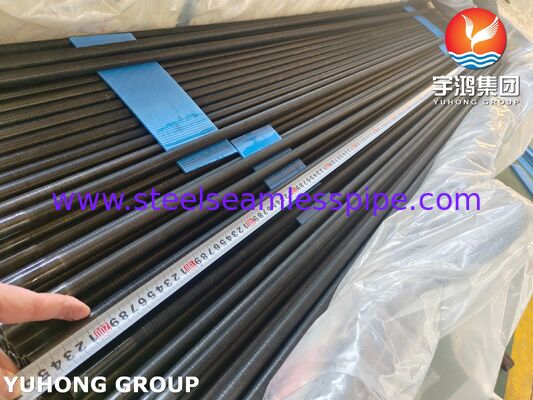

· Base Material: The tube core is made from ASTM A179/ASME SA179, a standard specification for seamless cold-drawn low-carbon steel tubes, known for good thermal conductivity and weldability.

· Fin Formation: The fins are not attached but are integrally formed from the tube wall itself through a precision cold-rolling or groove-rolling process. This creates a seamless, metallurgically bonded fin with excellent durability.

· "Low Fin" Geometry:

· Fin Height: Typically low, ranging from 0.8 mm to 1.5 mm (0.03" to 0.06").

· Fin Density: High, usually 19 to 40 fins per inch (fpi).

· Result: This design increases the outside surface area by a factor of 2.5 to 4 times compared to a plain tube of the same diameter, while maintaining a compact overall envelope.

2. Primary Advantages

· Enhanced Heat Transfer: Dramatically improves the shell-side heat transfer coefficient in a shell-and-tube heat exchanger. It is the most effective when the thermal resistance is on the tube's outside.

· Compact & Space-Efficient: Achieves much higher heat duty in the same shell diameter compared to plain tubes, or allows for a smaller, more economical exchanger for the same duty.

· Fouling Resistance: The continuous fin profile can be less prone to certain types of fouling than plain tubes and is easier to clean than high-fin tubes.

· Material Efficiency: Provides more heat transfer surface per kilogram of material than a plain tube.

· Direct Replacement: The root diameter (the diameter at the fin base) is typically designed to match the outer diameter of a standard plain tube, allowing it to use the same tube sheets, baffles, and shells.

3. Typical Applications

A179/SA179 Low Fin Tubes are ideal where the fluid on the shell side has a significantly lower heat transfer coefficient than the fluid inside the tube.

· Shell-and-Tube Heat Exchangers:

· Liquid Cooling/Vaporizing: Shell-side hydrocarbons, solvents, or high-viscosity fluids being cooled or condensed by water/steam inside the tubes.

· Intercoolers & Aftercoolers: Cooling compressed air or gas.

· Chiller and Refrigeration Evaporators: Where refrigerant evaporates on the finned shell side.

· Heat Recovery Systems.

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!